Welcome to the GMVC96 installation manual. This guide provides essential instructions for installing and configuring the furnace safely and efficiently. Always prioritize safety and follow the manual carefully to ensure proper functionality.

1.1 Overview of the GMVC96 Furnace

The GMVC96 furnace is a high-efficiency gas furnace designed for reliable heating performance. It features a modulating burner and variable-speed blower, ensuring precise temperature control and energy efficiency. This furnace is compatible with advanced thermostats, such as the CTK02AA modulating thermostat, which enhances its functionality. Its compact design allows for flexible installation options, making it suitable for various home configurations. The GMVC96 is built with durability and safety in mind, incorporating advanced safety features to protect your home and family. Proper installation is crucial to maximize its efficiency and performance, as outlined in this manual.

1.2 Importance of Proper Installation

Proper installation of the GMVC96 furnace is crucial for ensuring safety, efficiency, and reliability. Incorrect installation can lead to hazards, such as gas leaks, electrical issues, or improper venting, which may result in severe consequences. A well-installed system guarantees optimal performance, reducing energy consumption and extending the furnace’s lifespan. Compliance with local regulations and manufacturer guidelines is essential to avoid legal issues and ensure warranty validity. Additionally, proper installation minimizes the risk of malfunctions, providing consistent heating and peace of mind for the user. Always follow the manual’s instructions precisely to achieve a safe and efficient setup.

1.3 Key Components of the GMVC96 System

The GMVC96 system consists of several critical components essential for its operation; These include the furnace unit, a high-efficiency heat exchanger, and a modulating gas valve for precise temperature control. Additionally, the system incorporates a variable-speed blower motor and an advanced control board for optimal performance.

Other key components include the venting system, which ensures safe gas combustion byproducts removal, and a compatible thermostat, such as the CTK02AA, designed for modulating systems. The furnace also features electrical connections, gas line interfaces, and safety sensors to monitor and prevent potential hazards. Understanding these components is vital for proper installation and maintenance, ensuring reliability and efficiency in heating. Each part plays a role in delivering consistent, safe, and energy-efficient heating performance. Always refer to the manual for specific details on each component.

Pre-Installation Requirements

Ensure the installation site is prepared, safety precautions are in place, and all necessary tools and materials are available before starting the GMVC96 furnace installation.

2.1 Site Preparation for the Furnace

Proper site preparation is crucial for safe and efficient installation. Ensure the location is level, well-ventilated, and clear of flammable materials. The area must be accessible for utilities like power and gas. Check for proper drainage and ensure the floor can support the furnace’s weight. Verify that the space meets local building codes and manufacturer specifications. Clear any debris and ensure the area is dry. Proper combustion air supply must be available, and the furnace should be installed away from living spaces to minimize noise. Ensure all clearances from combustible materials are maintained as specified. This preparation ensures a safe and efficient installation process, aligning with safety guidelines and manufacturer recommendations.

2.2 Safety Precautions Before Installation

Before starting the installation of the GMVC96 furnace, ensure the area is clear of flammable materials and properly ventilated. Turn off the power supply and gas lines to avoid accidents. Always wear protective gear, including gloves and safety glasses, to prevent injuries. Ensure all tools and materials are compatible with the furnace specifications. Follow local safety regulations and manufacturer guidelines strictly. Never proceed without verifying that the system is safe to handle. Proper grounding and electrical connections are crucial to prevent shocks or fires. If unsure about any step, consult a licensed professional. Safety should always be the top priority to avoid risks during and after installation.

2.3 Tools and Materials Needed

To successfully install the GMVC96 furnace, gather the necessary tools and materials. Essential tools include a drill, screwdrivers, wrenches, pliers, and a multimeter for electrical connections. Additionally, ensure you have a gas line installer kit, venting components, and insulation materials. Safety gear like gloves and goggles is crucial. Proper tools and materials ensure a safe and efficient installation process.

Installing the GMVC96 Furnace

Installation requires careful planning and adherence to safety guidelines. Mount the furnace securely, connect electrical components precisely, and ensure proper gas line and venting setup for optimal performance and safety.

3.1 Mounting the Furnace in the Desired Location

Mounting the GMVC96 furnace requires careful planning and precision to ensure stability and proper operation. Begin by preparing the installation site, ensuring it is level, dry, and free from obstructions. Use the provided mounting brackets to secure the furnace to the wall or floor, adhering to the manufacturer’s specifications. Ensure the furnace is plumb and level using a spirit level to avoid operational issues. Once mounted, verify that all connections, such as gas lines and electrical components, are accessible for further installation steps. Always follow local building codes and safety guidelines to guarantee a safe and efficient setup. Proper mounting is crucial for optimal performance and longevity of the furnace.

3.2 Connecting Electrical Components

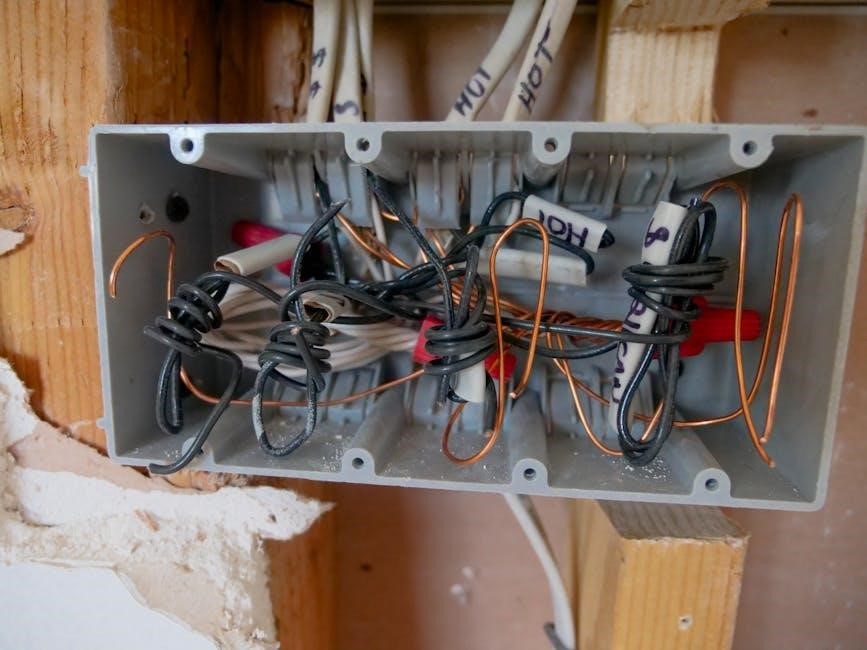

Connecting the electrical components of the GMVC96 furnace requires careful attention to detail to ensure safe and proper installation. Begin by shutting off the main power supply before handling any wiring. Refer to the wiring diagram provided in the manual to identify the correct connections for the thermostat, blower motor, and control board. Use appropriately sized wires and ensure all connections are secure to prevent loose contacts. Test for short circuits or open circuits using a voltage tester to verify the system’s integrity. Always follow local electrical codes and safety standards. If unsure, consult a licensed electrician to avoid potential hazards. Proper electrical connections are critical for the furnace’s efficient operation and safety. Double-check all wiring before restoring power to the system.

3.3 Gas Line Installation and Safety Checks

Proper gas line installation is critical for the safe operation of the GMVC96 furnace. Ensure the gas line is correctly sized and constructed with approved materials. Secure all connections tightly to prevent leaks. Conduct a gas leak test using a soap solution or an electronic gas leak detector. Verify that the gas pressure matches the furnace’s specifications. Always follow local building codes and safety standards. After installation, perform a final safety check to ensure the system operates correctly. If any issues arise, consult a qualified professional immediately. Proper installation and safety checks are essential to prevent hazards and ensure reliable furnace performance.

3.4 Venting System Setup and Requirements

Proper venting is critical for the GMVC96 furnace to operate safely and efficiently. The venting system must be installed according to local building codes and manufacturer specifications. Use approved materials like PVC or ABS for vent pipes, ensuring they are airtight and appropriately sized based on the furnace’s capacity. The venting system should be terminated outside, at least 12 inches above the roof or 3 feet away from any nearby windows or doors to prevent gas re-circulation. Ensure all connections are sealed tightly to avoid leaks. After installation, test the system for leaks by pressurizing it and applying soapy water to connections. Proper venting ensures safe removal of combustion byproducts and maintains indoor air quality. Always follow the manual’s guidelines for venting configuration to meet safety and performance standards.

Wiring and Thermostat Configuration

Ensure compatibility with thermostats like the CTK02AA modulating model. Follow the wiring diagram for proper connections. Configure settings for optimal performance and energy efficiency, checking compatibility first.

4.1 Compatible Thermostat Options

For optimal performance, the GMVC96 furnace requires a compatible thermostat. Recommended options include the CTK02AA modulating thermostat, designed to work seamlessly with the system. Other compatible models are the CT4000 and CT3500, which support dual-fuel setups. Ensure the thermostat matches the furnace’s specifications to maintain efficiency and safety. Using a non-compatible thermostat may lead to suboptimal performance or safety issues. Always refer to the official compatibility list provided by the manufacturer to verify your thermostat choice. Proper pairing ensures advanced features like modulating operation and dual-fuel functionality work as intended. This step is crucial for both performance and safety, so double-check compatibility before installation.

4.2 Wiring Diagram for the GMVC96

The wiring diagram for the GMVC96 furnace is a critical component of the installation process. It provides a detailed visual representation of the electrical connections required for proper system operation. Ensure compatibility with the CTK02AA modulating thermostat, as it is specifically designed for this furnace. The diagram outlines the connections for the thermostat, blower motor, and gas valve, ensuring safe and efficient operation. Always follow the diagram step-by-step to avoid miswiring, which can lead to malfunctions or safety hazards. If unsure, consult a licensed electrician or refer to the manual for clarification. Proper wiring is essential for optimal performance and safety.

4.3 Configuring the Thermostat for Optimal Performance

Configuring the thermostat correctly ensures efficient and reliable operation of the GMVC96 furnace. Begin by programming the thermostat with your desired temperature schedule to maintain consistent comfort. Adjust temperature settings based on seasonal needs and occupancy patterns. For optimal performance, use a compatible thermostat, such as the CTK02AA, which supports advanced features like modulation. Ensure the thermostat is properly calibrated and connected to the furnace’s control board. Regularly review and update settings to adapt to changing conditions. Always refer to the thermostat’s user manual for specific instructions. Proper configuration enhances energy efficiency, system reliability, and overall performance, ensuring your GMVC96 furnace operates at its best.

Safety Considerations

Safety is critical when installing and operating the GMVC96 furnace. Always ensure proper ventilation, check for gas leaks, and follow electrical safety guidelines to prevent hazards.

5.1 Ensuring Proper Ventilation

Proper ventilation is crucial for the safe and efficient operation of the GMVC96 furnace. Ensure that all vents and air ducts are clear of obstructions, such as debris or pests, to maintain airflow. Regularly inspect the venting system for damage or corrosion, as leaks can lead to carbon monoxide hazards. Use approved venting materials and follow local building codes to prevent gas leaks. Proper ventilation also improves indoor air quality by removing combustion byproducts. Failure to maintain ventilation can result in reduced system performance or safety risks. Always refer to the manual for specific venting requirements and recommendations to ensure optimal functionality and safety. Regular maintenance is essential to uphold the system’s efficiency and reliability over time.

5.2 Gas Leak Detection and Prevention

Gas leak detection and prevention are critical for ensuring the safe operation of the GMVC96 furnace. Always use a gas detector to identify potential leaks during installation and maintenance. Inspect all gas lines and connections for damage or wear. Tighten all fittings securely and ensure they are sealed properly. Use approved materials for gas line installations to prevent corrosion or degradation. Regularly inspect the venting system to ensure proper airflow, as blocked vents can lead to unsafe conditions. If a gas leak is suspected, turn off the furnace immediately and consult a professional. Remember, safety is paramount to prevent hazards like explosions or carbon monoxide exposure. Always follow local regulations and manufacturer guidelines for gas line installations and maintenance.

5.3 Electrical Safety Best Practices

Ensure all electrical connections are properly grounded to prevent shocks and ensure safe operation. Use the correct wire gauge for the furnace’s electrical requirements to avoid overheating. Never overload circuits, as this can lead to electrical fires. Keep wires and connections away from heat sources to prevent damage. Always turn off the power supply before performing any electrical work. Use a voltage tester to confirm power is off. Install a GFCI outlet if required by local codes to enhance safety. Secure all wires neatly to avoid tripping hazards and ensure longevity. Adhere to local electrical codes and manufacturer guidelines for a safe installation. Remember, electrical safety protects both people and the system from potential hazards.

Troubleshooting Common Issues

Identify and resolve common furnace problems, such as ignition failures, thermostat incompatibility, and venting malfunctions. Refer to the manual for detailed diagnostic steps and solutions.

6.1 Furnace Ignition Problems

Furnace ignition issues are common and can stem from faulty igniters or gas supply problems. Ensure the gas valve is fully open and check for proper venting. If the igniter fails to light, inspect for dirt or damage. Clean or replace the igniter as needed. Verify thermostat settings and ensure it is compatible with the GMVC96. If issues persist, consult a professional to avoid safety hazards. Always follow the manual for troubleshooting to prevent further complications. Proper installation and maintenance are key to resolving ignition problems effectively.

6.2 Issues with Thermostat Compatibility

Thermostat compatibility issues can arise if the thermostat is not specifically designed for the GMVC96 system. Ensure the thermostat is compatible with modulating furnaces. Some users have reported issues with legacy dual-fuel installations, where the thermostat may fail to identify connected equipment. In such cases, check if the thermostat is configured correctly for dual-fuel operation. Additionally, ensure the CTK02AA modulating thermostat is used if required. If problems persist, consult the wiring diagram or contact a professional to verify the setup. Proper configuration is essential for optimal performance and safety. Always refer to the installation manual for specific instructions on thermostat compatibility and configuration.

6.3 Venting System Malfunctions

Venting system malfunctions can lead to unsafe operating conditions. Common issues include blockages, leaks, or improper vent pipe installation. If the furnace shuts down unexpectedly, check for error codes. Ensure vent pipes are clear of debris and securely connected. Inspect for signs of damage, dents, or gaps. Proper venting is critical for safe operation and efficiency. Refer to the troubleshooting section for detailed diagnostic steps. Always follow safety guidelines when inspecting or repairing the venting system. If issues persist, contact a qualified technician to resolve the problem and ensure compliance with safety standards. Regular maintenance can prevent such malfunctions and maintain optimal furnace performance. Always prioritize safety when addressing venting system issues.

Maintenance and Upkeep

Regular cleaning of filters and vents ensures optimal performance. Schedule annual professional inspections to maintain efficiency and safety.

7.1 Regular Cleaning of the Furnace

Regular cleaning of the GMVC96 furnace is essential for maintaining efficiency, safety, and performance. Start by turning off the power supply to the furnace before cleaning. Use a soft brush or vacuum to remove dust and debris from the exterior and interior surfaces. Pay special attention to the heat exchanger, as buildup can restrict airflow and reduce efficiency. Replace or clean air filters as recommended by the manufacturer to ensure proper air circulation. Additionally, inspect and clean the venting system to prevent blockages. Failure to clean regularly can lead to reduced performance, higher energy bills, or potential safety hazards. Always refer to the manual for specific cleaning instructions tailored to the GMVC96 model.

7.2 Inspecting the Venting System

Regular inspection of the venting system is crucial for safe and efficient operation. Ensure all vents are clear of obstructions, such as debris or nests, to maintain proper airflow. Check for any signs of damage, corrosion, or leaks in the vent pipes, as these can lead to safety hazards. Verify that all connections are secure and properly sealed. Additionally, inspect the vent termination points to ensure they are correctly installed and meet local building codes. Improper venting can result in reduced efficiency, safety risks, or equipment damage; Always refer to the manual for specific guidelines and consider hiring a professional for annual inspections to ensure compliance and optimal performance.

7.3 Scheduling Professional Maintenance

Regular professional maintenance is crucial for ensuring the GMVC96 furnace operates efficiently and safely. Schedule annual inspections with a qualified technician to check for wear, tear, and potential issues. During these visits, professionals will clean components, inspect the venting system, and ensure all electrical connections are secure. Maintenance helps prevent unexpected breakdowns, optimizes performance, and extends the furnace’s lifespan. Always use factory-authorized service providers to guarantee compliance with manufacturer guidelines. Additionally, maintain a record of all maintenance activities for future reference and warranty purposes. By prioritizing professional upkeep, you can ensure reliable heating and minimize the risk of costly repairs. Remember, a well-maintained system is essential for both safety and energy efficiency.

Thank you for following the GMVC96 installation manual. Proper installation ensures safety and efficiency. Review all steps to confirm everything is correctly set up for optimal performance and customer satisfaction.

8.1 Final Checks Before Operation

Before operating the GMVC96 furnace, perform a thorough inspection to ensure all components are correctly installed and functioning. Verify that electrical connections are secure, and gas lines are leak-free. Check the venting system for proper installation and clear any blockages. Ensure the thermostat is configured correctly and test it to confirm proper communication with the furnace. Inspect the ignition system for any signs of wear or damage. Test the furnace ignition to ensure it lights and operates smoothly. Finally, confirm that all safety features are activated and functioning as intended. These final checks are critical to ensure safe and efficient operation of the GMVC96 furnace.

8.2 Ensuring Customer Understanding of the System

It is crucial to ensure the customer fully understands the GMVC96 system’s operation, safety features, and maintenance requirements. Begin by explaining the furnace’s basic functionality, such as how it heats the home and the importance of proper ventilation. Highlight key safety features, like automatic shut-off in case of malfunctions. Demonstrate how to operate the thermostat, including setting temperatures and understanding energy-saving modes. Address common issues, such as ignition problems or thermostat compatibility, and provide guidance on troubleshooting. Emphasize the need for regular maintenance, like filter cleaning and vent inspections, to ensure optimal performance. Provide the customer with a copy of this manual and offer to answer any questions they may have. This ensures they feel confident and informed about their new system.

8.3 Importance of Following the Manual

Adhering to the GMVC96 installation manual is crucial for ensuring safety, efficiency, and compliance with manufacturer guidelines. Proper installation prevents hazards like gas leaks or electrical issues, safeguarding both the system and users. Failure to follow instructions may void warranties or lead to regulatory non-compliance. Additionally, correct setup minimizes the risk of malfunctions and ensures optimal performance. Always refer to the manual for specific instructions, as deviations can result in substandard operation or safety risks. By following the manual, installers can ensure a reliable and efficient heating system that meets all safety and operational standards.